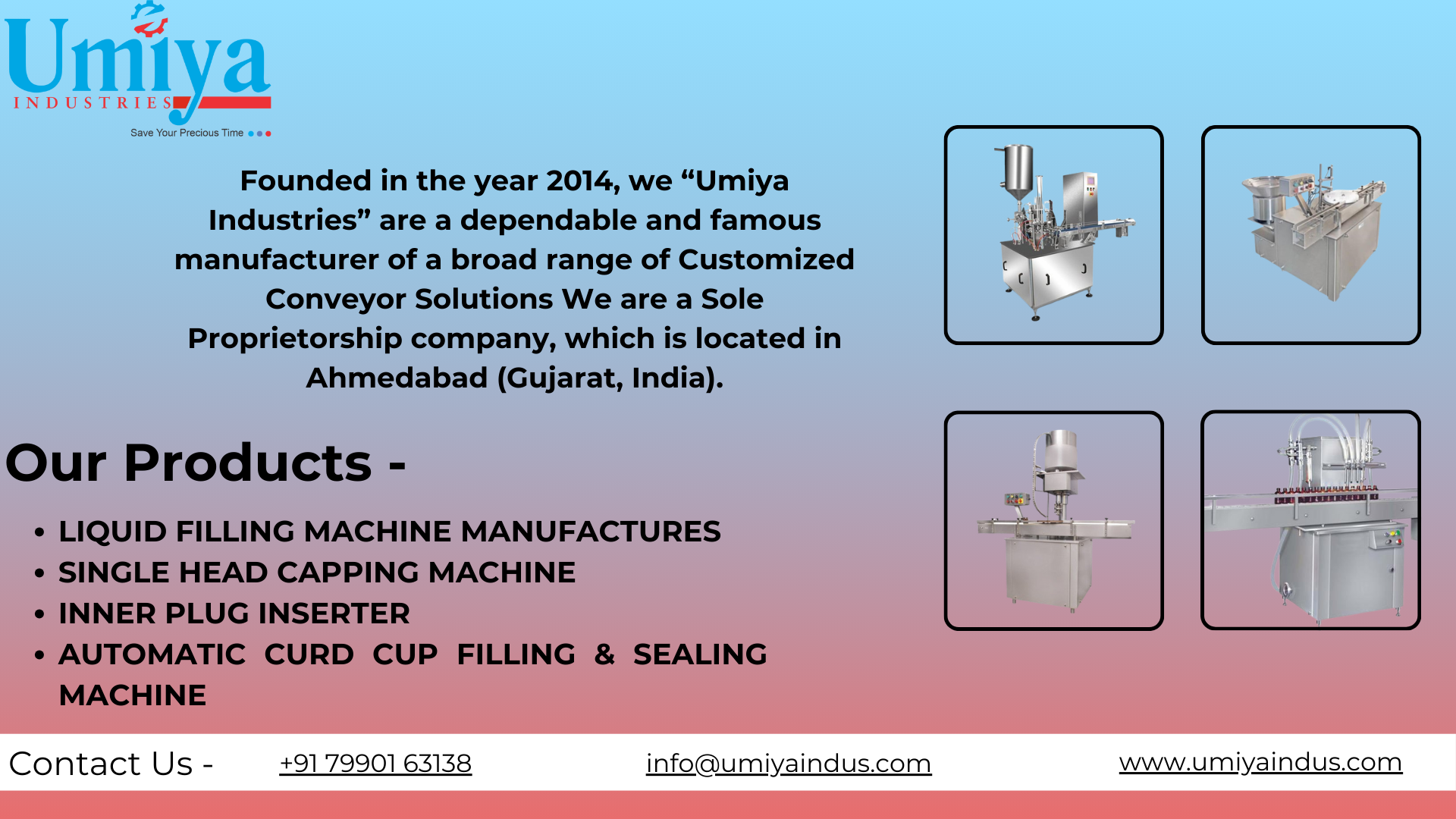

Single Head Capping Machine

Single

Head Capping Machine

Single

Head Capping Machine – Description

A Single Head Capping Machine is a compact,

efficient, and highly reliable packaging solution designed to securely seal

containers with caps of various sizes and types. This semi-automatic or fully

automatic machine is ideal for low to medium-volume production lines. It is

widely used in industries such as pharmaceuticals, cosmetics, food &

beverages, chemicals, and more. The machine ensures accurate and consistent

capping, reducing spillage, contamination, and manual labor.

Engineered for precision, the single head capping machine

can handle a range of container shapes and cap types—screw caps, ROPP caps,

press-on caps, and more—making it a versatile asset in modern production

environments.

Top

Features and Their Uses

|

Feature |

Use / Benefit |

|

Single Capping Head |

Provides consistent torque and sealing for each bottle,

improving accuracy. |

|

Adjustable Torque Settings |

Prevents over-tightening or under-tightening of caps. |

|

Stainless Steel Body |

Corrosion-resistant, easy to clean—ideal for hygienic

industries like pharma. |

|

Compact Design |

Saves floor space; suitable for small production areas. |

|

Easy Tool-less Changeover |

Enables quick switching between different bottle or cap

sizes. |

|

PLC Control (optional) |

Automates the process, increases operational efficiency. |

|

Safety Guards |

Ensures operator safety during high-speed operations. |

|

Bottle Centering System |

Holds the bottle in position during capping, minimizing

error. |

|

Foot Pedal Operation (manual) |

Allows operator control for each capping cycle in

semi-auto versions. |

|

Low Maintenance |

Reduces downtime and operating costs. |

Applications

of Single Head Capping Machine

The single head capping machine is extensively used in:

- Pharmaceutical

Industry: Sealing bottles of syrups, tablets, and supplements.

- Food

& Beverage Industry: Capping sauces, juices, water bottles, and

condiments.

- Cosmetic

Industry: Sealing lotion, shampoo, and cream containers.

- Chemical

Industry: Capping bottles of cleaning agents, pesticides, and

industrial fluids.

- Ayurvedic

and Herbal Products: Sealing oils, herbal tonics, and powders.

- Dairy

Products: Closing containers of milk, curd, or flavored beverages.

10 Most

Asked FAQs

Q1: What is a single head capping machine?

A: It is a machine used to apply caps to bottles or containers, one at a

time, ensuring a secure and consistent seal.

Q2: Can it handle different types of caps and bottles?

A: Yes, it can work with various cap sizes, types (screw, ROPP,

flip-top), and bottle shapes.

Q3: Is this machine suitable for small businesses?

A: Absolutely! Its compact design and ease of use make it ideal for

small-scale and startup operations.

Q4: What materials is the machine made from?

A: Generally, high-grade stainless steel (SS 304 or SS 316), ensuring

durability and hygiene.

Q5: How fast can it cap bottles?

A: Depending on the model, it can cap 20 to 40 bottles per minute.

Q6: Is the torque adjustable?

A: Yes, to ensure the right tightness and avoid damaging caps or

containers.

Q7: Does it require skilled labor?

A: Minimal training is needed—operators can quickly learn to use it

efficiently.

Q8: Can it be integrated into an existing production

line?

A: Yes, especially the automatic version can easily be integrated with

conveyors and filling machines.

Q9: What kind of maintenance does it require?

A: Routine cleaning and periodic checks of moving parts are sufficient

for smooth operation.

Q10: Is it customizable?

A: Many manufacturers offer customizations based on bottle size, cap

type, and automation level.

Contact

Us For More Details On :

Call -

+91 79901 63138

Facebook - www.facebook.com/profile.php?id=100067626623882

Instagram - www.instagram.com/umiyaindustries2015

Youtube - www.youtube.com/@UmiyaIndustries-mn8fm

Website - www.umiyaindus.com

Email -

umiyaindustries16102012@gmail.com | info@umiyaindus.com

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.