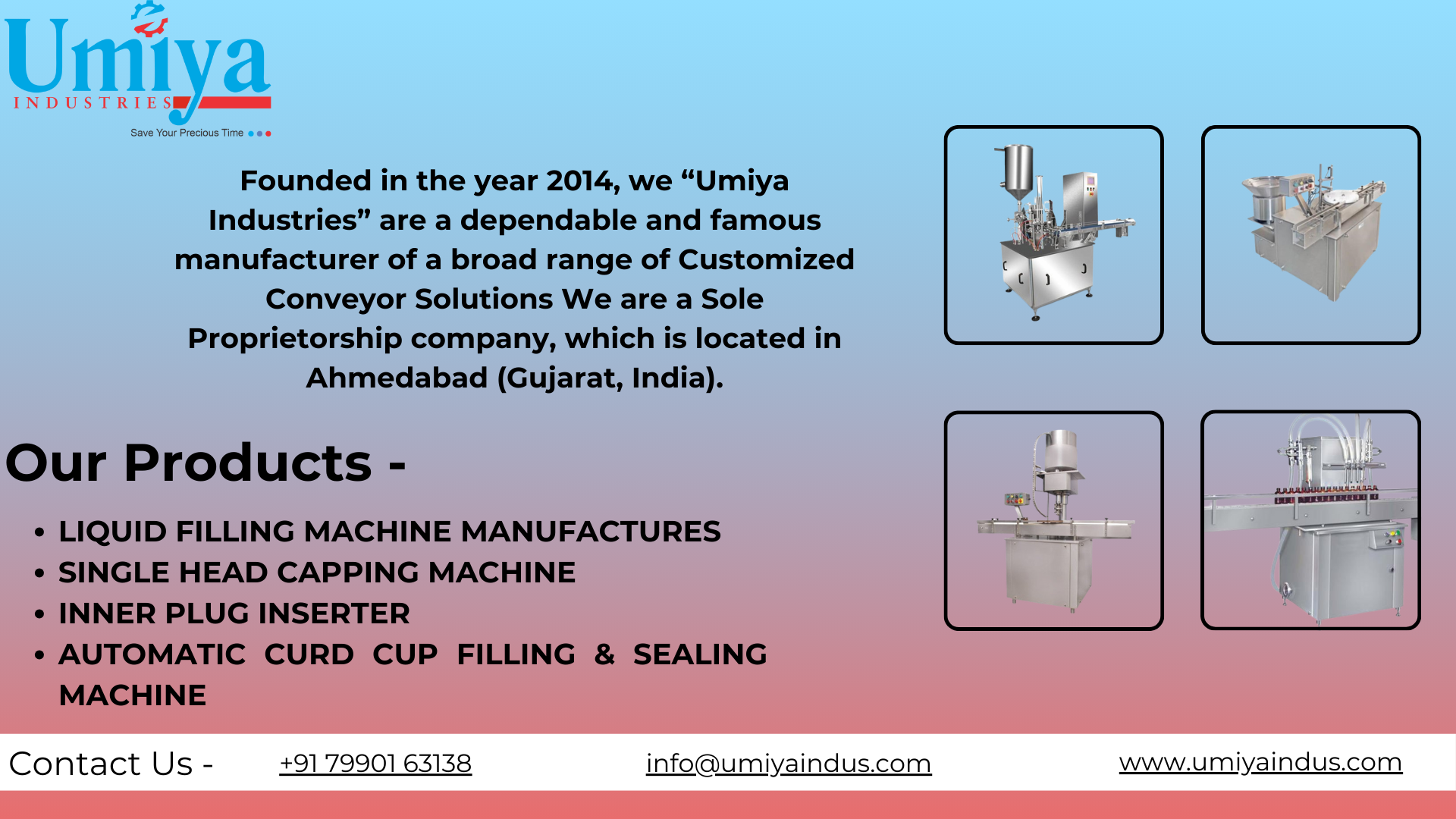

Monoblock Filling & Capping Machine

Monoblock

Filling & Capping Machine

Description:

A Monoblock Filling & Capping Machine is an

advanced packaging solution designed to perform both filling and capping

operations in a single compact unit. This highly efficient machine is widely

used in industries such as pharmaceuticals, food & beverage, cosmetics,

chemicals, and more. It ensures accurate filling and perfect sealing of bottles

or containers, maintaining hygiene and minimizing human intervention.

This machine integrates precision technology for liquid

filling, coupled with an automated capping system, providing high-speed

operation and consistency. It is suitable for filling liquids like syrups,

oils, juices, milk, cleaning agents, lubricants, and other fluid products.

Applications

of Monoblock Filling & Capping Machine:

- Pharmaceutical Industry (Syrup, Tonic, Oral Solutions)

- Food

& Beverage Industry (Juice, Milk, Water, Flavored Drinks)

- Cosmetics

Industry (Shampoo, Lotion, Oil, Perfumes)

- Chemical

Industry (Cleaning Agents, Disinfectants, Pesticides)

- Ayurvedic

& Herbal Industry

- Dairy

Industry

- Health

Supplements Manufacturing

- Lubricant

Oils Industry

- Edible

Oil Bottling Plants

- Distilleries

& Breweries (Liquor Bottling)

Key

Features of Monoblock Filling & Capping Machine:

- Compact and space-saving design

- Synchronized

filling and capping system

- High-speed

operation for mass production

- No

bottle – No fill – No cap mechanism

- Adjustable

filling volumes

- Accurate

liquid filling with minimum wastage

- Stainless

steel construction for hygienic operations

- PLC

Control System with Touch Screen HMI

- Automatic

bottle feeding and ejection

- Easy

changeover for different bottle sizes

- Anti-drip

filling nozzles

- Safety

features with emergency stop

- Low

maintenance & long service life

- Servo

or Pneumatic driven filling options

- Rotary

or Inline bottle movement system

Uses of

Monoblock Filling & Capping Machine:

- Automatic filling and sealing of PET, HDPE, Glass Bottles

- Ideal

for liquid packaging in pharmaceutical and food industries

- Ensures

contamination-free and leakage-proof packaging

- Increases

productivity and reduces labor cost

- Suitable

for small to large-scale production units

- Versatile

use for viscous and non-viscous liquids

Top 10

Frequently Asked Questions (FAQs)

1. What is a Monoblock Filling & Capping Machine?

? It is a packaging machine that integrates both

liquid filling and capping functions in a single unit, ensuring faster and

efficient production.

2. Which industries commonly use this machine?

? Pharmaceutical, Food & Beverage, Cosmetics, Chemicals,

Dairy, Ayurveda, Lubricant, and Distilleries are major users.

3. What types of liquids can it fill?

? It can fill water, syrup, juice, oil, chemicals, shampoo,

milk, lubricants, and similar liquids.

4. Can it handle different bottle sizes?

? Yes, most machines come with adjustable settings for

various bottle sizes and shapes.

5. What is the speed or output capacity of this machine?

? Speed varies between 30 to 200 bottles per minute,

depending on the model and product viscosity.

6. Is the machine suitable for viscous liquids?

? Yes, it can fill both viscous and non-viscous liquids with

customized filling nozzles.

7. Does it have an automatic capping system?

? Yes, it automatically places and tightens caps on bottles

after filling.

8. Is operator skill required to run this machine?

? Basic operator training is sufficient, thanks to PLC-based

automatic controls.

9. How is hygiene maintained in this machine?

? Stainless steel (SS 304/316) contact parts, CIP system

compatibility, and drip-free filling nozzles ensure hygiene.

10. Can this machine be customized?

? Yes, most manufacturers offer customization based on

production requirements, bottle design, and product type.

Conclusion:

A Monoblock Filling & Capping Machine is an ideal

choice for industries looking for automation, accuracy, and speed in their

packaging line. It reduces operational time, ensures product safety, and

enhances overall productivity.

Contact

Us For More Details On :

Call - +91

79901 63138

Facebook - www.facebook.com/profile.php?id=100067626623882

Instagram - www.instagram.com/umiyaindustries2015

Youtube - www.youtube.com/@UmiyaIndustries-mn8fm

Website - www.umiyaindus.com

Email -

umiyaindustries16102012@gmail.com | info@umiyaindus.com

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.