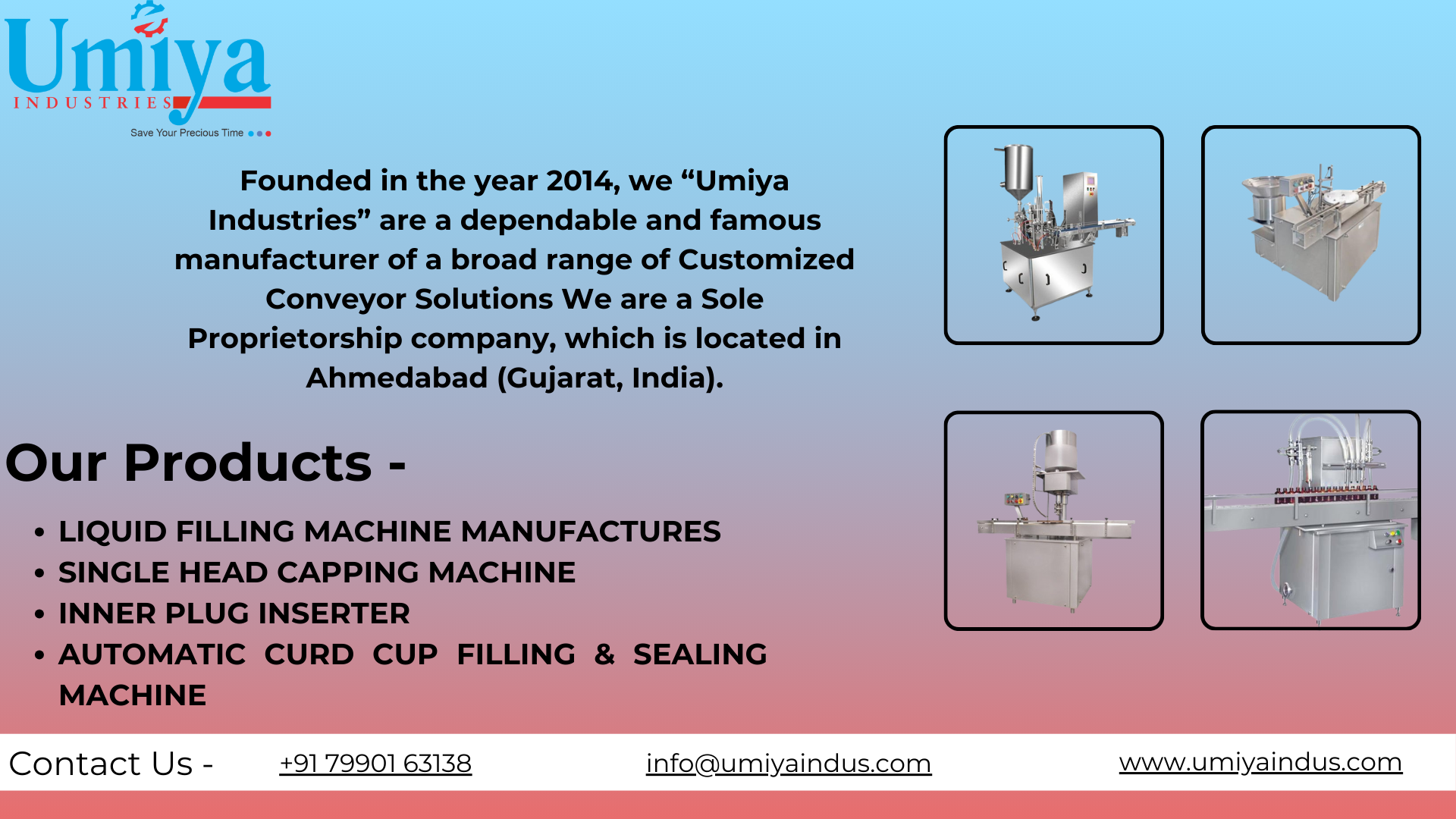

Linear Capping Machine

Linear

Capping Machine

A Linear Capping Machine is an advanced automated

system designed to securely place and tighten caps on bottles or containers in

a production line. It is engineered for high-speed operations and consistent

torque control, making it ideal for industries like pharmaceuticals, cosmetics,

beverages, food processing, and chemicals. With linear (straight-line)

movement, this machine supports various cap types such as screw caps, press-on

caps, ROPP caps, and flip-tops—offering unmatched versatility, reliability, and

scalability in packaging operations.

Many Linear Capping Machines come equipped with a cap

feeder, torque adjustment, PLC control system, and automatic bottle spacing,

making them a staple in medium- to large-scale production setups.

Top 10

FAQs about Linear Capping Machine

Q1. What is a Linear Capping Machine?

A Linear Capping Machine is used to apply and tighten caps onto bottles

automatically in a straight-line configuration on the production line.

Q2. What types of caps can this machine handle?

It can handle screw caps, press-on caps, flip tops, ROPP caps, snap-fit caps,

and more, depending on the customization.

Q3. What industries use linear capping machines?

Pharmaceuticals, food & beverages, cosmetics, chemicals, and personal care

product manufacturers use them widely.

Q4. What bottle materials are compatible?

The machine supports PET, HDPE, glass, aluminum, and other container materials.

Q5. Can it handle different bottle sizes and shapes?

Yes, it can be adjusted or customized for multiple bottle sizes and geometries.

Q6. Is operator intervention required?

Minimal. Most models are semi-automatic or fully automatic with user-friendly

controls.

Q7. What is the average output capacity?

Typically ranges from 30 to 200 bottles per minute, depending on the model.

Q8. Can it be integrated with other machines?

Yes, it integrates seamlessly with filling machines, labeling machines, and

conveyors.

Q9. How is the torque adjusted?

Torque can be manually or digitally adjusted based on cap requirements to avoid

under- or over-tightening.

Q10. What are maintenance requirements?

Regular lubrication, sensor checks, and belt inspections are typically required

for smooth operation.

Features

of Linear Capping Machine with Uses

|

Feature |

Use/Benefit |

|

Automatic Cap Placement |

Ensures consistent cap application, improving efficiency

and reducing manpower. |

|

Adjustable Torque Control |

Prevents over-tightening or loose capping, safeguarding

product integrity. |

|

PLC Touchscreen Interface |

Offers user-friendly control and monitoring. |

|

Cap Feeding System (Bowl/Conveyor) |

Automatically sorts and feeds caps into the system,

speeding up operations. |

|

No-Bottle No-Cap System |

Prevents wastage and avoids dry runs when no container is

present. |

|

Stainless Steel Body |

Corrosion-resistant and GMP-compliant for food and

pharmaceutical use. |

|

Servo or Pneumatic Head Options |

Ensures precise capping and adaptability based on

production needs. |

|

Multiple Cap Compatibility |

Accommodates various cap types without changing the

machine. |

|

Safety Sensors and Emergency Stops |

Enhances operator safety during operation. |

|

High-Speed Output |

Increases productivity and supports large batch

manufacturing. |

Applications

of Linear Capping Machine

|

Industry |

Application |

|

Pharmaceuticals |

|

|

Food & Beverage |

Sealing bottles of water, sauces, juices, and edible oils. |

|

Cosmetics & Personal Care |

Capping lotions, shampoos, perfumes, and creams. |

|

Chemicals & Pesticides |

Sealing containers for household cleaners, pesticides, and

oils. |

|

Dairy Products |

Capping flavored milk, yogurt bottles, and buttermilk

containers. |

|

Ayurvedic/Herbal |

Capping herbal tonics, syrups, and oil bottles. |

|

Lubricants Industry |

Sealing bottles of engine oil and industrial lubricants. |

Contact

Us For More Details On :

Call -

+91 79901 63138

Facebook - www.facebook.com/profile.php?id=100067626623882

Instagram - www.instagram.com/umiyaindustries2015

Youtube - www.youtube.com/@UmiyaIndustries-mn8fm

Website - www.umiyaindus.com

Email -

umiyaindustries16102012@gmail.com | info@umiyaindus.co

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.