Auger Powder Filling Machine

Auger

Powder Filling Machine

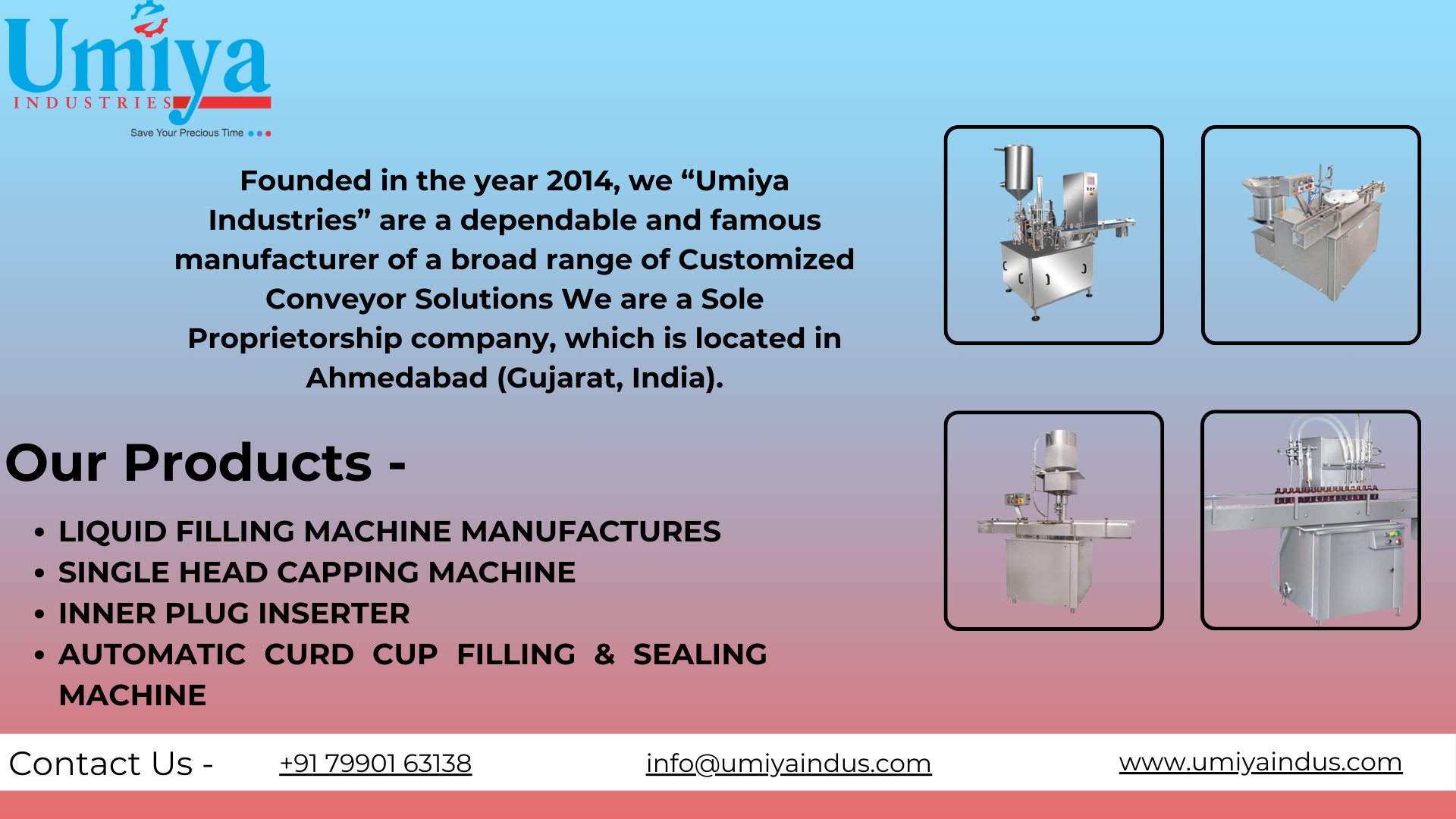

An Auger Powder Filling Machine is a highly efficient

and accurate packaging equipment designed for filling and dispensing

free-flowing and non-free-flowing powders into containers like bottles,

pouches, jars, cans, or sachets. It operates using an auger screw mechanism

that rotates to measure and dispense a precise amount of powder product.

Widely used in industries like food, pharmaceuticals,

chemicals, cosmetics, and agriculture, the Auger Powder Filler ensures clean,

fast, and dust-free powder filling with minimal wastage. It is suitable for a

wide range of powders such as protein powder, spices, milk powder, flour,

cosmetic powders, talcum powder, detergent powder, and more.

This machine can operate as a standalone unit or be

integrated into automatic packaging lines, improving productivity, reducing

labor, and enhancing packaging consistency.

Applications

of Auger Powder Filling Machine

- Food

Industry ? Protein Powder, Flour, Spices, Milk Powder, Coffee Powder,

Nutrition Powders

- Pharmaceutical

Industry ? Medicinal Powders, Dietary Supplements

- Chemical

Industry ? Detergent Powder, Fertilizer Powder, Industrial Chemicals

- Cosmetic

Industry ? Talcum Powder, Face Powder, Cosmetic Dusting Powder

- Agriculture

Industry ? Pesticide Powder, Animal Feed Powder, Fertilizer Powder

- Nutraceutical

Industry ? Health Supplements, Herbal Powders

- Dairy

Industry ? Milk Powder, Whey Protein Powder

- Baking

Industry ? Baking Powder, Cocoa Powder

- Plastic

& Polymer Industry ? Powdered Resins, Additives

- Any

Powder-Based Product Packaging

Key

Features of Auger Powder Filling Machine

- Accurate & Consistent Powder Filling

- PLC

Control System with Touch Screen Interface

- Adjustable

Fill Volume

- Stainless

Steel Construction for Hygiene & Durability

- Easy

to Clean & Maintain

- Servo

Motor Driven for High Precision

- Anti-Dust

Design with Dust Collection Option

- Compact

Design, Space Saving

- Suitable

for Free-flow & Non-Free-flow Powders

- Optional:

Bottle/Pouch Holding Mechanism, Conveyor Integration

Top 10

FAQs on Auger Powder Filling Machine

Q1. What is an Auger Powder Filling Machine?

An Auger Powder Filling Machine uses a rotating auger

screw to accurately fill powdered products into containers.

Q2. What types of powders can be filled using an Auger

Filler?

It can handle free-flowing powders like salt, flour, and

milk powder, as well as non-free-flowing powders like spices, protein, and

pharmaceutical powders.

Q3. Is the machine suitable for both bottles and pouches?

Yes, Auger Powder Filling Machines can be customized

to fill bottles, pouches, jars, cans, and other containers.

Q4. What is the filling accuracy of the machine?

Typically, the filling accuracy is ±1% depending on product

characteristics and machine configuration.

Q5. Can I adjust the filling volume?

Yes, the filling volume can be easily adjusted through the

PLC or manually, depending on the model.

Q6. Does it generate dust during filling?

Most machines come with an anti-dust design and optional

dust collection systems for a cleaner work environment.

Q7. Is the machine available in semi-automatic and fully

automatic versions?

Yes, depending on production needs, both semi-automatic and

fully automatic auger fillers are available.

Q8. What is the production speed?

Production speed varies based on powder type and container

size but typically ranges from 10 to 60 fills per minute.

Q9. Is it easy to clean and maintain?

Yes, the stainless steel construction ensures easy cleaning,

and modular parts allow for quick maintenance.

Q10. Can it be integrated into a packaging line?

Yes, the Auger Powder Filling Machine can be

integrated with conveyors, sealing machines, labeling systems, and other

automation solutions.

Contact

Us For More Details On :

Call - +91

79901 63138

Facebook - www.facebook.com/profile.php?id=100067626623882

Instagram - www.instagram.com/umiyaindustries2015

Youtube - www.youtube.com/@UmiyaIndustries-mn8fm

Website - www.umiyaindus.com

Email -

umiyaindustries16102012@gmail.com | info@umiyaindus.com

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.